Jul, 29 2025

Jul, 29 2025

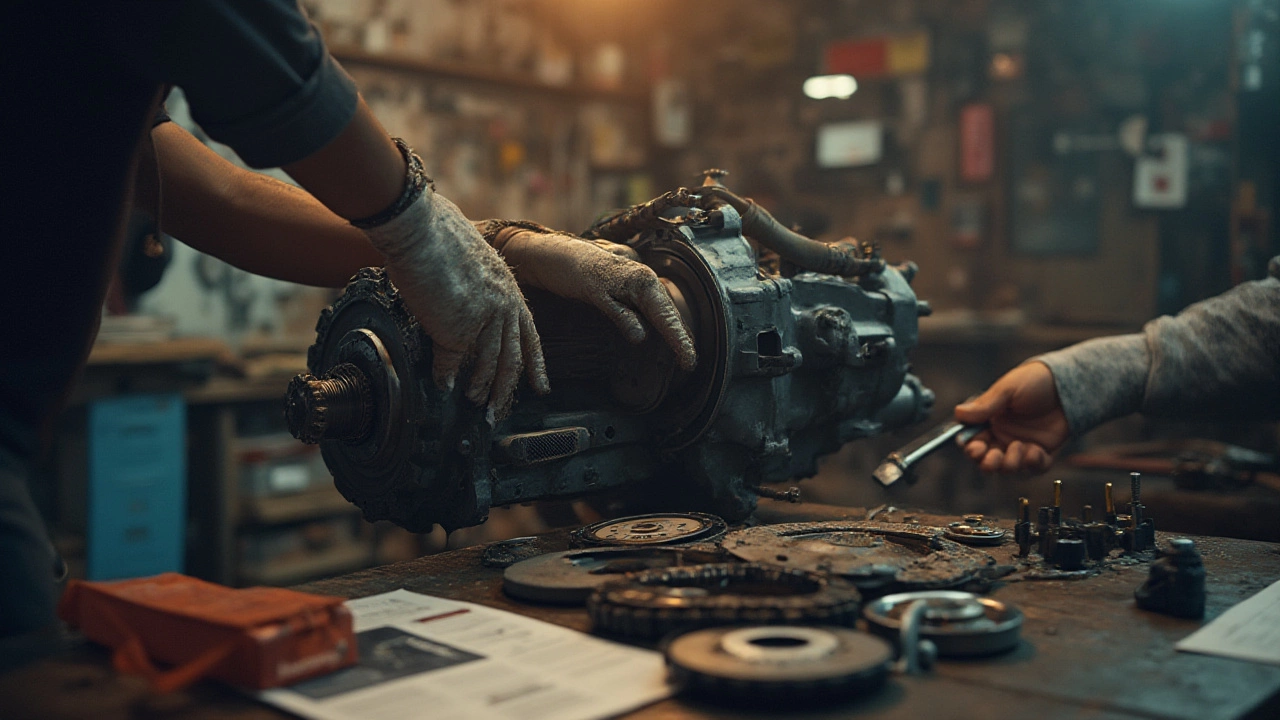

You hear the word clutch and immediately think of that sinking feeling when your pedal drops to the floor and your car just isn’t grabbing gears. Maybe you’re stuck in your driveway, or maybe—if you’re lucky—you noticed the warning signs early and got ahead of the drama. The question isn’t whether the clutch will need to be replaced, but when. And if you’re staring down this job, you’re probably wondering: How many hours does it actually take to replace a clutch kit? The answer isn’t as simple as a flat number—and the range might surprise you. A clutch job is no afternoon walk in the park. Sometimes, even the pros get stuck longer than they expected.

What Goes Into Replacing a Clutch Kit?

People sometimes imagine a clutch kit swap as a simple bolt-on affair—take one out, put one in. The truth looks very different. The process is a multi-step marathon, even for seasoned mechanics. It all starts with putting the car safely on a lift (or, at home, on jack stands—a move that instantly adds to your hours if you don’t have access to a lift). From there, you’ll disconnect the battery to avoid any surprises, and then begin clearing out the space between you and the clutch itself. That usually means pulling off the driveshaft on rear-wheel drives, or the axles on front-wheel drives, dropping the transmission, and sometimes the exhaust and subframe. Only then can you reach the pressure plate, clutch disc, and release bearing.

Removal is rarely quick, since you’re often dealing with rusted or seized-up bolts, finicky wiring harnesses, and 100-pound hunks of transmission. Once the clutch is visible, the real fun begins: Making sure you have the right parts, checking for damage to neighboring bits like the flywheel or pilot bearing, and comparing old and new before putting everything back together. Even a shop running like a well-oiled machine might spend more time fixing the unexpected than actually swapping the clutch itself. The little things—stripped threads, missing hardware, a leaky rear main seal—often eat up hours if you aren’t careful. A seemingly simple clutch kit swap can snowball into extra work if those hidden issues appear.

Want to know just what you’re in for? Here’s a breakdown of average labor times—emphasis on replace clutch kit:

| Car Type | Average Labor Hours | Common Surprises |

|---|---|---|

| Small FWD Coupe (e.g., Honda Civic) | 4-6 hours | Axle nuts stuck, seized bolts, fitment issues |

| Modern AWD Turbo (e.g., Subaru WRX) | 7-10 hours | Drivetrain removal, stubborn axles |

| Pickup Truck, RWD (e.g., Ford F-150) | 6-8 hours | Heavy transmissions, transfer case extras |

| Older Euro Sport Sedan (e.g., BMW 3-series) | 8-12 hours | Tight underbodies, exhaust, custom shifter linkage |

Of course, these are just averages. I’ve seen clutches swapped in three hours flat by a pit-crew-level tech with power tools and zero snags, and I’ve heard of backyard wrenchers in rust-belt towns pulling all-nighters stumped by a snapped exhaust manifold bolt.

Why Do Some Clutch Replacements Take So Much Longer?

The range is wild for a reason. The big killers for time? Car design, corrosion, DIY situations, and surprise repairs. Front-wheel-drive cars are notorious for being fiddly because everything’s jammed up together. You might have to actually drop the whole subframe just to get the transmission out—a process that means removing multiple suspension parts, steering links, and even part of the exhaust. That’s a whole new set of alignment bolts to replace, and it adds up.

AWD cars crank it up a notch. Expect nearly every major piece of the drivetrain to come loose—think center diffs, axles, and possibly driveshafts. These extras ramp up the clock, especially if the car’s been through harsh winters and nothing wants to budge. On the other hand, some rear-wheel-drive cars are built for quick clutch jobs because of easier access.

Your tools and experience also play huge roles. Professional shops with lifts, transmission jacks, and air tools chew through the job in far less time than most home mechanics with hand tools and a patch of driveway. But even in a shop, hidden problems slow things down: stripped threads, snapped bolts, or worn throwout bearings needing last-minute replacement. Stuff like a leaky rear main seal behind the flywheel will leave a mechanic feeling like they’re chasing their own tail. If you're doing the clutch swap yourself, expect a steep learning curve. Print out a full repair guide for your specific car, and double the professional book time to set your expectations.

A pro might quote 4-6 billable hours for an easy job, but if the car has seen a tough life, those hours can quickly balloon. One smart pro tip—before booking the shop, ask if they’ve replaced a clutch kit on your exact car before. Some shops keep internal cheat-sheets about which cars are time-sinks. And if you want to save a little on labor, help out by busting loose those rusty bolts with penetrating oil a day ahead, or even pulling your own exhaust parts—if you know what you’re doing.

What Impacts Clutch Replacement Time—And How Can You Speed It Up?

Everyone’s heard a horror story about a “weekend” clutch job that turned into a month-long ordeal. What separates the smooth, same-day clutch swap from the endless struggle? It comes down to a mix of preparation, tool quality, and tackling bolt-on chaos before it snowballs.

- Car model: Some brands and models are just plain harder to work on. Engineering quirks or tight undercarriages will chew up time.

- Year and corrosion: A car from Texas will typically be way faster to wrench compared to one from the Midwest. Rusted bolts slow down any job.

- Transmission size: Smaller, lighter transmissions come out easier and take less muscle and time.

- Other repairs: If you discover a leaking transmission seal or a badly scored flywheel while you’re in there, it’s best to fix them at the same time, even if it adds hours now. Otherwise, you’ll just be back under the car soon.

- Access to tools and lifts: A hydraulic lift can shave hours off even the messiest job. Transmission jacks and air tools are game changers.

If you want to cut down your own repair time, here are a couple of hacks mechanics use:

- Pre-soak suspect bolts with quality penetrating oil—WD-40 is decent, but products like PB Blaster or Kroil are better.

- Take tons of photos during teardown, especially for wiring harnesses and coolant lines. Saves time on reassembly.

- Replace anything worn or leaking while you have it open, like the pilot bearing or rear main seal. Repeating this job for a $7 part feels bad.

- Lay out new clutch components alongside the old ones before you install, just to triple-check nothing is missing.

- Let gravity help you—if your driveway isn’t flat, aim so the transmission can be maneuvered out more easily.

If you’re working with a buddy, trade off the grunt work. That’s how the pros move fast—one guy loosens bolts, the other extracts parts. And don’t skip the repair manual for your vehicle (seriously): torque specs and bolt order matter a lot, especially when putting the transmission back. Trying to save a few minutes by guessing can cost you way more time on round two.

How Much Should You Budget for Labor Hours—and Can You DIY?

If you take your car to a shop, clutch replacement labor is billed by the hour, and the industry standard is to use a book time from labor guides like Chilton or AllData. These guides base their numbers on an ideal scenario, which often doesn’t match real-world conditions. For a typical front-wheel-drive sedan, expect the manual to say 5-6 hours. Now, add a safety margin if your car is “well seasoned” or if you live somewhere that sees road salt.

Average hourly labor rates in July 2025 hover between $110 and $185 depending on your city or region. So even a quick clutch job usually hits your wallet for $500 in labor alone, while more involved jobs (Subarus, older BMWs) might top $1,300 just on shop time. Dealers tend to quote a higher rate, while independent mechanics might underbid but take longer if they don’t have factory tools. And yes, some shops charge flat rate regardless of how long it actually takes, so if the mechanic is skilled and gets done early, you still pay the quote—but if they hit a snag, you’re protected from a ballooning bill.

If you’re thinking about doing it yourself, the good news is you can save all that labor cash, but you’ll spend a ton of time and sweat. Plan realistically: A first-timer should block out a weekend at minimum, and have access to a second car or a friend for backup. Renting a transmission jack and a real torque wrench will save both your back and your sanity. And don’t be afraid to call it if you’re getting in over your head. There’s no shame in letting a pro finish the job if things get dicey.

One cool fact: Some clutch kits now include throwout and pilot bearings, alignment tools, and detailed step-by-step instructions, cutting down on hunting for extra pieces or searching forums. Always use genuine or high-quality aftermarket parts—no one wants to do this job twice when cheap parts fail.

To land on a real number for your car, check the labor guide online, add 15% for stuck bolts or little surprises, and ask your local shop if they’ve seen any curveballs with your make and model. Simple, right? No one wants a clutch job to get stuck in the shop for a week because someone forgot to order a $15 pilot bushing.