Oct, 27 2025

Oct, 27 2025

Flywheel Noise Diagnosis Tool

Identify Your Flywheel Noise

Select the noise you're hearing and when it occurs to get an analysis of what it might mean.

Ever hear a weird grinding, chirping, or clunking sound when you let off the gas or shift gears? If you’ve got a manual transmission, that noise might not be your clutch-it could be your flywheel. A worn or damaged flywheel doesn’t just make noise; it can wreck your clutch, strain your starter, and even leave you stranded. Most people blame the clutch first, but the flywheel is often the real culprit-and it’s usually hidden from view until something breaks.

What Does a Bad Flywheel Sound Like?

A healthy flywheel is silent. It’s a heavy steel disc bolted to the engine’s crankshaft, smoothing out power pulses and giving the clutch something solid to grip. When it goes bad, it doesn’t just stop working-it starts screaming.

The most common noise is a grinding or scraping sound, especially when you’re shifting or letting the clutch out slowly. It sounds like metal on metal, like someone dragging a file across a wrench. This usually means the friction surface is worn down or cracked. If you’ve got a dual-mass flywheel (common in modern cars), you might hear a clunking or knocking noise when you accelerate or decelerate. It’s like a loose rock rattling inside the engine bay.

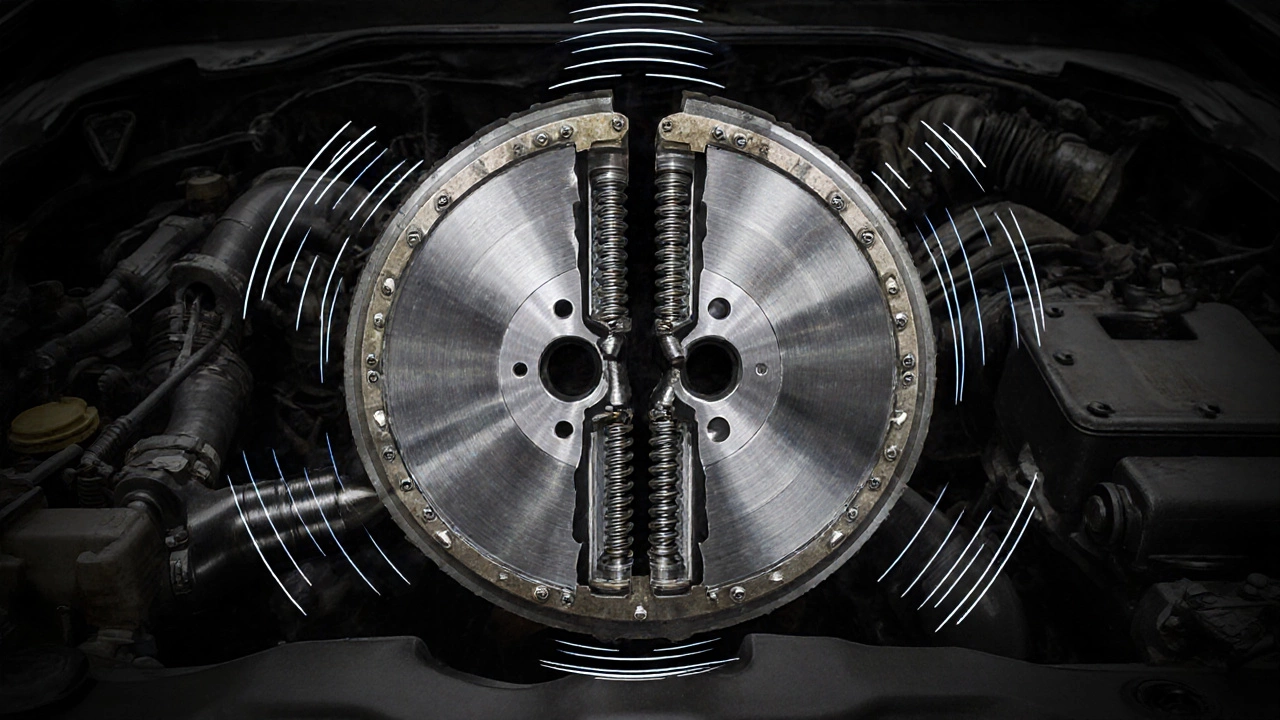

Some people describe a chirping or squealing noise at idle or low RPMs. That’s often a sign the damper springs inside a dual-mass flywheel have broken. The springs are meant to absorb engine vibrations, and when they snap, the flywheel starts vibrating violently against the clutch plate. The noise gets louder under load-like when you’re pulling away from a stop or climbing a hill.

Then there’s the rattling noise that sounds like a bag of bolts in the bellhousing. That’s usually the clutch release bearing grinding against a cracked or warped flywheel surface. If you hear this, don’t wait. The flywheel is already failing, and the clutch is about to follow.

Why Does a Flywheel Fail?

Flywheels are built to last, but they’re not indestructible. The main reasons they go bad:

- Clutch abuse-riding the clutch, slipping it too much, or letting it burn out from stop-and-go traffic wears down the friction surface fast.

- Heat damage-if your clutch overheats from hard driving or towing, the heat transfers to the flywheel. That can warp it or cause cracks in the surface.

- Manufacturing defects-some aftermarket flywheels, especially cheap ones, use low-grade steel that cracks under stress.

- Age and mileage-dual-mass flywheels have internal springs and dampers that wear out after 80,000 to 120,000 miles. High-mileage cars often need them replaced, even if the clutch still looks fine.

Here’s the catch: a bad flywheel doesn’t always show up on a visual inspection. You can’t see cracks or warping without removing the clutch. That’s why mechanics often replace the flywheel when they’re already replacing the clutch. It’s cheaper than doing it twice.

Dual-Mass vs. Solid Flywheels: Know the Difference

Not all flywheels are the same. There are two main types:

- Dual-mass flywheel (DMF): Used in most cars made after 2000. It has two separate discs connected by springs and dampers. It smooths out engine vibrations, especially in diesel engines or those with fewer cylinders. But those springs wear out. When they do, you get clunking, rattling, or a weird vibration through the pedal.

- Solid flywheel: A single piece of steel. Found in older cars and performance vehicles. Simpler, tougher, and cheaper to replace. But it transmits more engine vibration to the cabin. No dampers means no springs to break-but it’s harder on the transmission.

If your car came with a dual-mass flywheel, replacing it with a solid one might save you money now-but you’ll feel every engine pulse. Some drivers hate it. Others don’t mind, especially if they drive hard. Just know: switching from DMF to solid often requires a new clutch and sometimes even a different release bearing.

How to Tell If It’s the Flywheel or the Clutch

Most people assume the clutch is the problem because it’s the part you’re actively using. But here’s how to tell the difference:

- Clutch problems usually mean slipping (engine revs but car doesn’t accelerate), difficulty shifting, or a spongy pedal. The noise is usually quiet or absent.

- Flywheel problems make noise even when the clutch is fully engaged. You hear it when you’re driving normally-not just when shifting.

- If the noise changes with engine RPM (not gear), it’s likely the flywheel. If it only happens when pressing or releasing the pedal, it’s probably the clutch release bearing or pressure plate.

There’s one simple test: start the car in neutral. Let it idle. Now, gently press the clutch pedal halfway down and hold it. If you hear a new noise-like a rattle or chirp-that’s the release bearing. If the noise stays the same, it’s likely the flywheel.

What Happens If You Ignore It?

Driving with a bad flywheel isn’t just noisy-it’s dangerous.

A cracked flywheel can shatter under load. If that happens while you’re driving, it can send metal shards into the bellhousing, destroy the clutch, damage the transmission input shaft, or even crack the engine block. That’s not a $500 repair. That’s a $3,000+ rebuild.

Even before it breaks, a warped flywheel causes the clutch to wear unevenly. You’ll get clutch chatter, vibration, and premature failure. You might replace the clutch twice before realizing the flywheel was the root cause.

And if you’ve got a dual-mass flywheel with broken springs, the vibration can damage your transmission mounts, crankshaft sensor, or even the starter motor over time.

When to Replace the Flywheel

You should replace the flywheel when:

- You hear any of the noises described above

- Your clutch is being replaced (it’s always the right time to check the flywheel)

- Your car has over 80,000 miles and you’ve never replaced it

- You’ve had repeated clutch failures without obvious cause

- There’s visible scoring, cracks, or warping on the surface (visible after clutch removal)

Don’t wait for a catastrophic failure. Most mechanics recommend replacing the flywheel whenever the clutch is changed, especially on high-mileage vehicles. It’s a small extra cost now to avoid a huge bill later.

How Much Does Flywheel Replacement Cost?

Parts alone:

- Solid flywheel: $150-$300

- Dual-mass flywheel: $400-$900

Labor is the big part. Because the flywheel is behind the transmission, you need to remove the transmission or engine to access it. That’s 5-8 hours of labor depending on the car.

Total cost range:

- Simple solid flywheel replacement: $800-$1,500

- Dual-mass replacement: $1,200-$2,500

Some shops offer clutch-and-flywheel kits that include the pressure plate, release bearing, and pilot bearing. These can save you $100-$200 compared to buying parts separately. Just make sure the kit matches your car’s exact model and engine code.

Can You Reuse a Flywheel?

Only if it’s in perfect condition-and even then, it’s risky.

A solid flywheel can sometimes be resurfaced if it’s only lightly scored. A machine shop can grind it flat again. But if there are cracks, deep grooves, or heat damage, it’s done. No amount of resurfacing fixes a cracked flywheel.

Dual-mass flywheels can’t be resurfaced at all. Once the springs or dampers are worn, the whole unit is trash. You can’t rebuild them. You have to replace them.

Here’s the rule: if you’re spending money to replace the clutch, replace the flywheel too. It’s not a suggestion-it’s insurance.

What to Do Next

If you suspect your flywheel is bad:

- Listen closely. Note when the noise happens: at idle? During shifts? Under load?

- Check your mileage. If you’re over 80,000 miles and it’s a DMF, assume it’s worn.

- Don’t delay. A noisy flywheel is a ticking time bomb.

- Take it to a reputable mechanic who works on manual transmissions. Ask them to inspect the flywheel when they pull the clutch.

- Get a quote for a full clutch kit with a new flywheel. Don’t let them talk you into reusing the old one.

Replacing a flywheel isn’t fun. But it’s one of those repairs that saves you from worse problems down the road. Don’t ignore the noise. It’s not just annoying-it’s a warning.